The generator also has strong adaptive capabilities, which can automatically adjust welding parameters according to different materials, thicknesses, and shapes of plastic parts, achieving one click operation, greatly reducing the skill requirements for operators, and improving the flexibility and adaptability of the production line. At the same time, the built-in fault self checking and alarm system can monitor the real-time operation status of the equipment, detect and solve problems in a timely manner, and ensure the safety and stability of production.

With the continuous advancement of automation technology and artificial intelligence, the fully automatic ultrasonic plastic welding generator will become more intelligent and efficient. For example, combining machine vision technology to achieve precise positioning and real-time monitoring of the welding process; Utilize big data analysis to optimize welding parameters and further improve welding quality and efficiency. At the same time, environmental protection and energy conservation will also become an important direction for the development of this field, promoting the full automatic ultrasonic plastic welding generator to play a more important role in green manufacturing.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

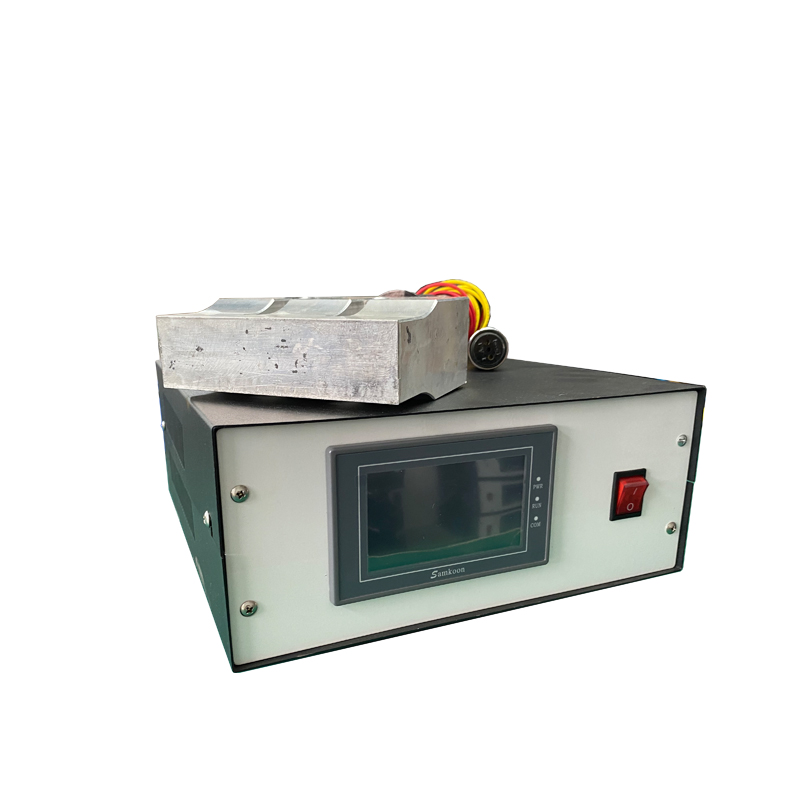

4000W Automatic Control Ultrasonic Power Welding Generator Transducer Booster Horn For Ultrasonic Pvc Welding Machine_Company dynamics_Pulisonic Ultrasonic

Last:Automatic Control Ultrasonic Frequency Welding Generator Transducer Booster Horn For Ultrasonic Meta

Next:Automatic Control Ultrasonic Metal Welding Generator Transducer Booster Horn For Ultrasonic Copper C