After the technical mystery of piezoelectric ultrasonic welding driven generator, we have to mention its wide application and innovation in modern industrial manufacturing. With the rapid development of materials science and precision machining technology, piezoelectric ultrasonic welding technology has gradually replaced traditional welding methods with its advantages of high efficiency, environmental protection, and low energy consumption, and has shone in fields such as automotive electronics, medical equipment, and aerospace.

Especially in the automotive electronics industry, piezoelectric ultrasonic welding drive generators, with their precise energy control and fast response capabilities, can achieve reliable connections to precision components in small spaces, such as the welding of connection harnesses, sensors, and motherboards in battery management systems, effectively improving the overall performance and safety of automotive electronic systems. At the same time, its non-contact welding characteristics avoid potential damage to electronic components caused by high temperatures, ensuring the stability of product quality.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

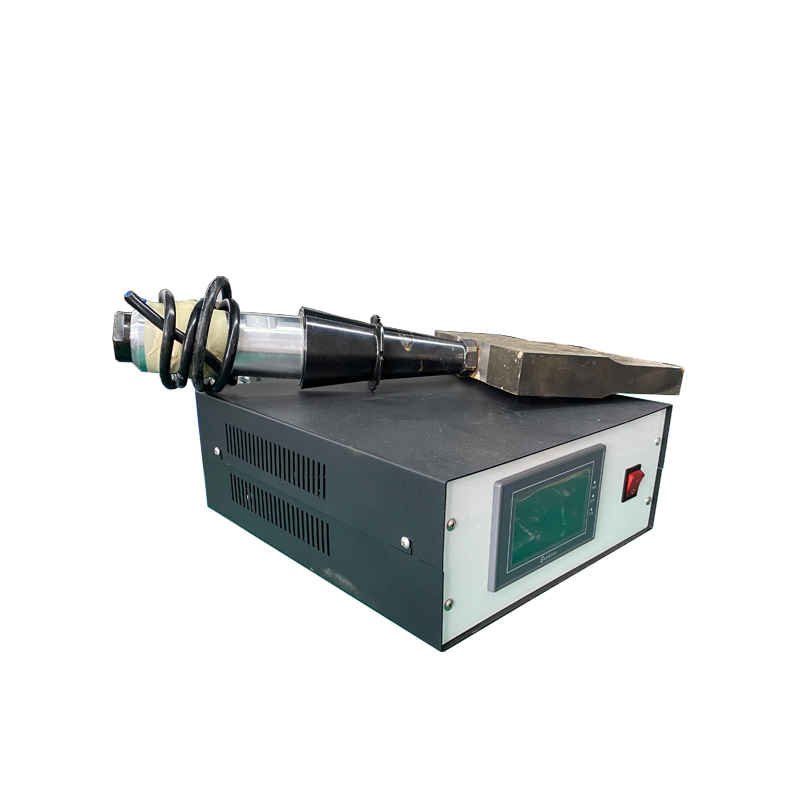

Automatic Ultrasonic Spot Welding Generator Transducer Booster Horn For Ultrasonic Acrylic Plastic Welding Machine_Company dynamics_Pulisonic Ultrasonic

Last:Automatic Ultrasonic Frequency Welding Generator Transducer Booster Horn For Non-woven Welding Machi

Next:Automatic Ultrasonic Metal Welding Generator Transducer Booster Horn For Sealing Edge Ultrasonic Wel