Advantages of circulating filtration ultrasonic cleaner:

1. There is no penetration. Because the ultrasonic action occurs in the whole liquid, the surface of all objects that can contact with the liquid can be cleaned, and it has more unique effect on objects with complex shapes and many gaps.

2. There is no damage. Traditional manual or chemical cleaning often produces mechanical wear or chemical corrosion, while ultrasonic cleaning will not cause any damage to the object.

3. Wash everything. No matter what kind of dirt is attached to the hard object, as long as the object can be immersed in the cleaning fluid, it will not be washed clean. In addition, when the appropriate cleaning agent is used for objects with different properties, the penetration and dissolution of the cleaning agent is enhanced by ultrasound, and it will play a full role, so the cleaning will be completely new.

Applicable industries:

1) Machinery industry: removal of antirust grease; Cleaning of measuring tools; Oil and rust removal of mechanical parts; Cleaning of engine, carburetor and auto parts; Dredging and cleaning of filter and filter screen.

(2) Surface treatment industry: oil and rust removal before electroplating; Cleaning before ion plating; Phosphating treatment; Remove carbon deposit; Remove oxide scale; Remove polishing paste; Metal workpiece surface activation treatment, etc.

(3) Instrument industry: high cleanliness of precision parts, cleaning before assembly, etc.

(4) Electronics industry: removing rosin and welding spots on printed circuit boards; Cleaning of mechanical and electronic parts such as high-voltage contacts.

(5) Medical industry: cleaning, disinfection, sterilization of medical devices, cleaning of laboratory utensils, etc.

(6) Semiconductor industry: high cleanliness cleaning of semiconductor chips.

(7) Watch head and decoration industry: remove sludge, dust, oxide layer, polishing paste, etc.

(8) Chemical and biological industries: cleaning and descaling of laboratory utensils.

(9) Optical industry: oil removal, perspiration removal and ash removal of optical devices.

(10) Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

(11) Petrochemical industry: cleaning and dredging of metal filters, cleaning of chemical containers and exchangers, etc.

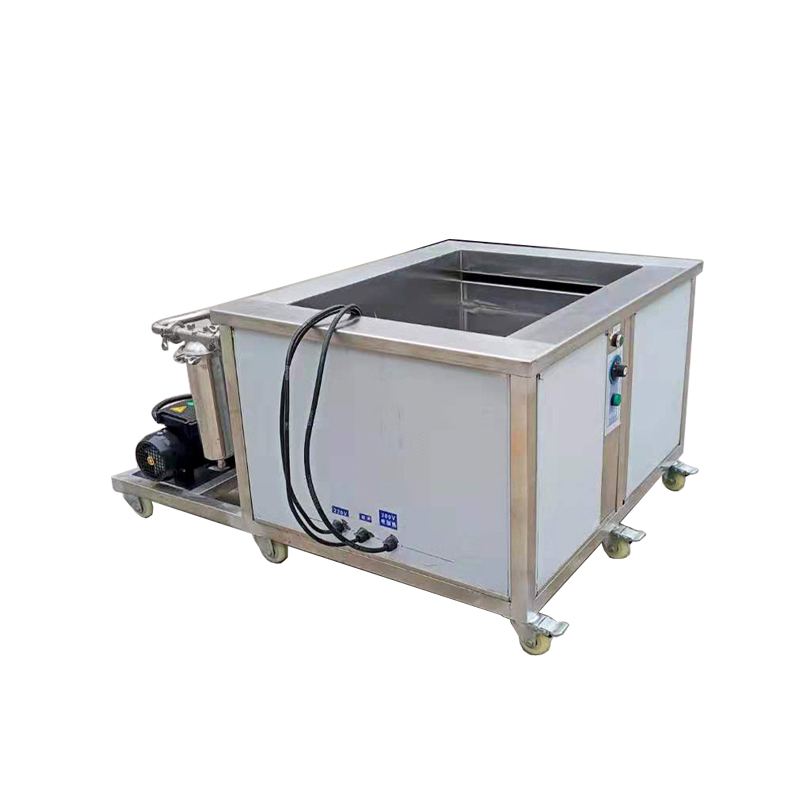

Irregular Complex Components Ultrasonic Filter Cleaner SUS 304 Stainless Steel Tank_Company dynamics_Pulisonic Ultrasonic

Last:Cyclic Auto Control Circulating Ultrasonic Filter Cleaner Big Part Automotive Parts Washer

Next:Industrial Ultrasonic Cleaning Machine With Oil Filter System For Aircraft Parts Automobile hub Clea