Ultrasonic Generator For PVC ABS Plastic Welding Equipment

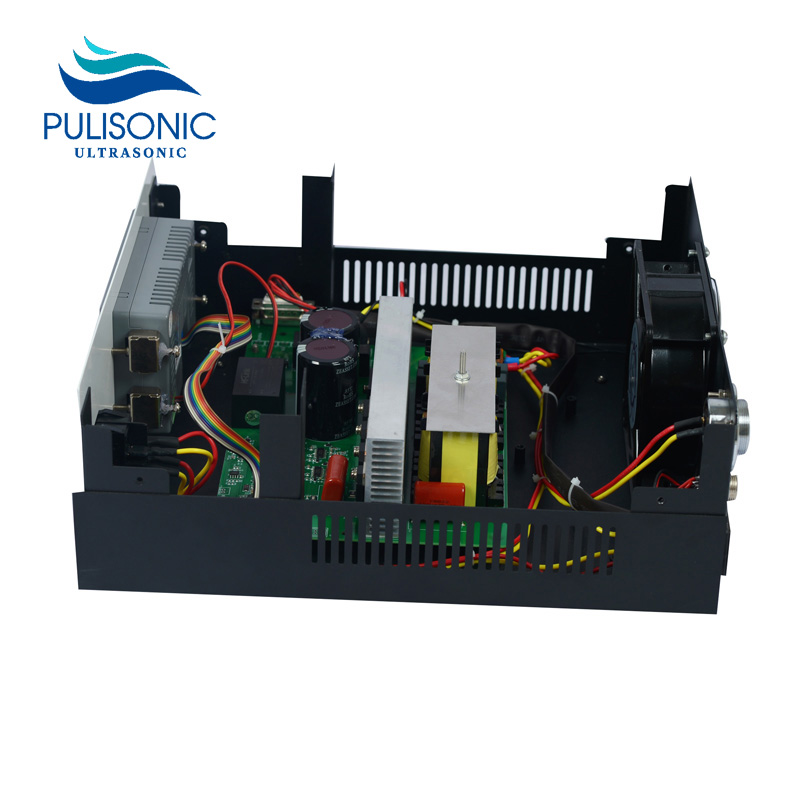

When the ultrasonic welding generator is started, it will automatically search the resonance frequency of vibrator and welding head, detect the power supply of the system, detect the frequency range of welding head, and check whether the key fails. Operating frequency, memory point confirmation. Finally, judge whether the welding head current is too high. After confirming that it is normal, the start key lock of each part will be automatically released, otherwise the equipment cannot be started normally.

1、 Four features of intelligent automatic frequency tracking plastic welding machine:

1. Automatic frequency tracing: the intelligent frequency control system eliminates the inconvenience of manual frequency modulation, automatically detects the sound wave overload, automatically adjusts to the working frequency band, and tracks the working resonance point in real time. The machine runs more stably, the temperature of the vibration group remains at the lowest point, the temperature of the welding head rises, the frequency changes with the follow-up, and the machine adjusts automatically.

2. Stepless amplitude: stepless amplitude control, increasing by 5%, large and small rubber parts can be welded, effectively reducing defective products such as puncture and scald

3. There are three modes:

a. Time mode, precise time control, no time difference, the longest time is 9.999 seconds, up to 1ms (one thousandth of a second).

b. Depth mode, built-in grating ruler, with an accuracy of 0.01mm, and the welding distance can be set to effectively avoid the influence of air pressure, unstable voltage and high-low error of rubber parts on the final welding.

c. In power mode, when the welding reaches the set power, the wave is sent at the end

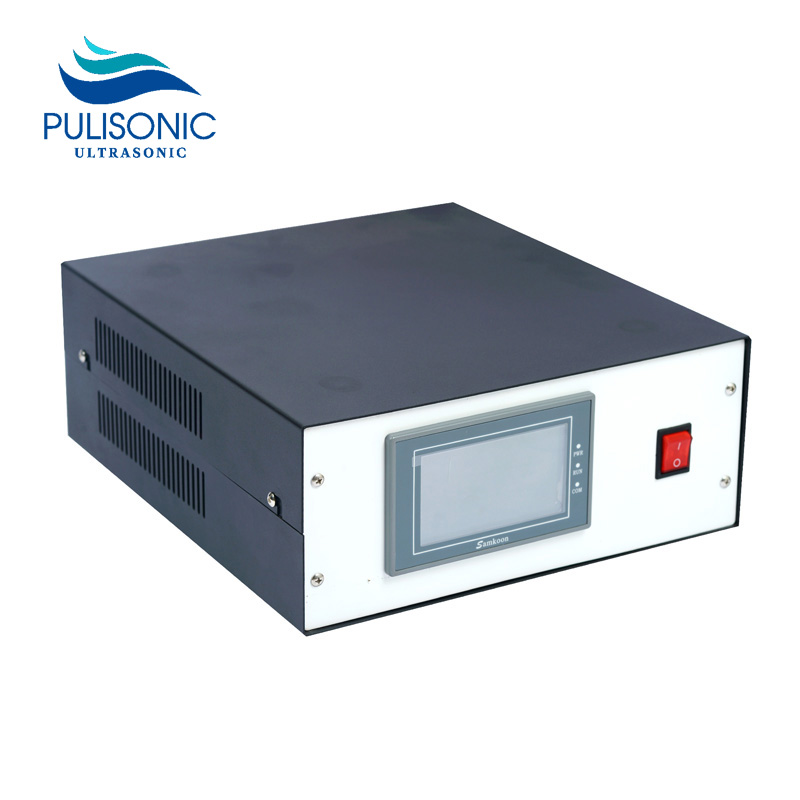

4. 4.3-inch touch screen display, digital input is simpler and more accurate than the old dial code operation, and the counter can input the initial value to facilitate counting and memory. Chinese and English interface operation (optional) is convenient for foreign procurement.

Power(W) | Frequency (KHz) | |

PLS-HJDY-500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

PLS-HJDY-800 | 800W | 28KHZ,30KHZ,35KHZ |

PLS-HJDY-1000 | 1000W | 20KHZ,28KHZ,30KHZ,35KHZ |

PLS-HJDY-1500 | 1500W | 15KHZ,20KHZ,28KHZ |

PLS-HJDY-2000 | 2000W | 15KHZ,20KHZ |

PLS-HJDY-2600 | 2600W | 15KHZ,20KHZ |

PLS-HJDY-3200 | 3200W | 15KHZ |

| PLS-HJDY-4200 | 4200W | 15KHZ |

Ultrasonic Generator For PVC ABS Plastic Welding Equipment_Ultrasonic Generator_Pulisonic Ultrasonic

Last:Ultrasonic Generator For Automatic Mask Manufacturing Machine

Next:200W-600W Ultrasonic PCB Driver Board With Control Board