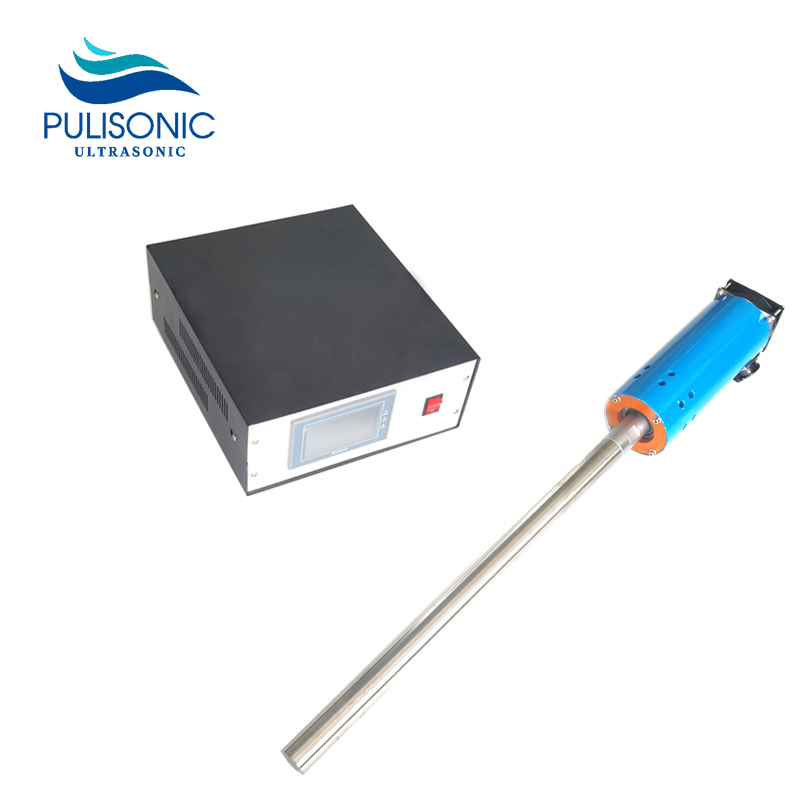

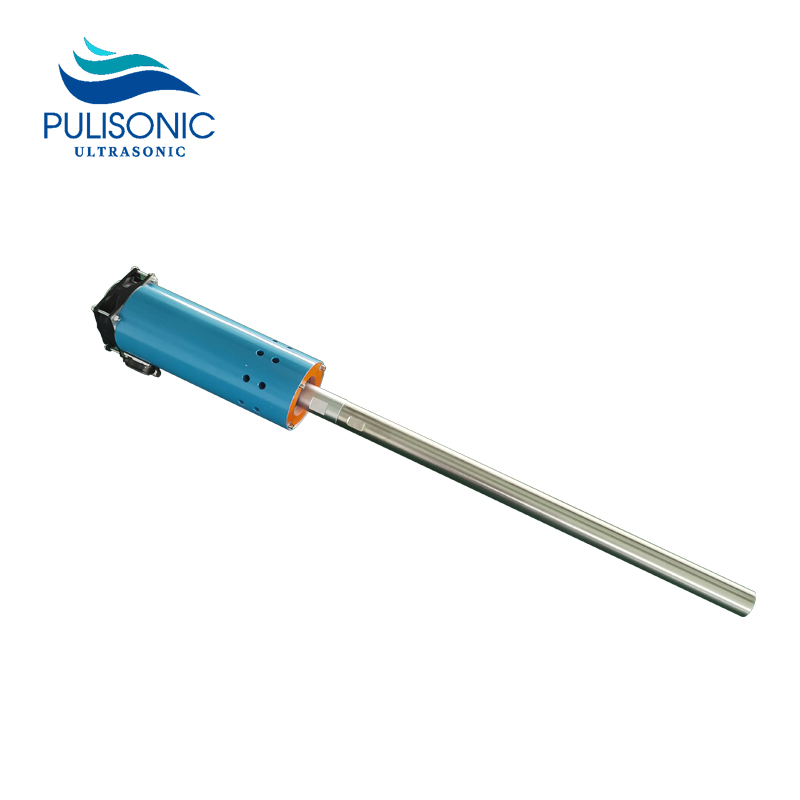

20khz Ultrasonic Biodiesel Reactor For Biodiesel Production

Ultrasonic biodiesel reactor probe sonicator

The key to biodiesel preparation using ultrasonic biodiesel reactor is the catalytic transesterification of fatty acid glyceride with methanol and other low-carbon alcohols. Ultrasonic can obviously strengthen the transesterification reaction, especially for heterogeneous reaction system, which can significantly enhance its mixing (emulsification) effect and promote intermolecular contact reaction, so that the reaction originally required to be carried out under high temperature (high pressure), It can be completed at room temperature (or close to room temperature) and shorten the reaction time. Ultrasound is used not only in the transesterification reaction process, but also in the separation process of reaction mixture. The yield of biodiesel can exceed 99% within 5 minutes, while it takes more than 1 hour to adopt the conventional batch reactor system. Ultrasonic processing can shorten the separation time of 5-10 waste oil and swill oil refining biodiesel technology and equipment required for conventional mixing to less than 15 minutes. In addition, ultrasonic processing can also reduce the amount of catalyst required by 50% 60% and improve the purity of by-product glycerol.

Type | PLS-HLCSB1000 | PLS-HLCSB1500 | PLS-HLCSB2000 |

Frequency | 20KHz | 20KHz | 20KHz |

Power | 1000W | 1500W | 2000W |

20khz Ultrasonic Biodiesel Reactor For Biodiesel Production_Ultrasonic Transducer_Pulisonic Ultrasonic

Last:Ultrasonic Tubular Transducer Vibration Rod For Cleaning

Next:20khz Ultrasonic Probe Sonicator For Extraction Biodiesel