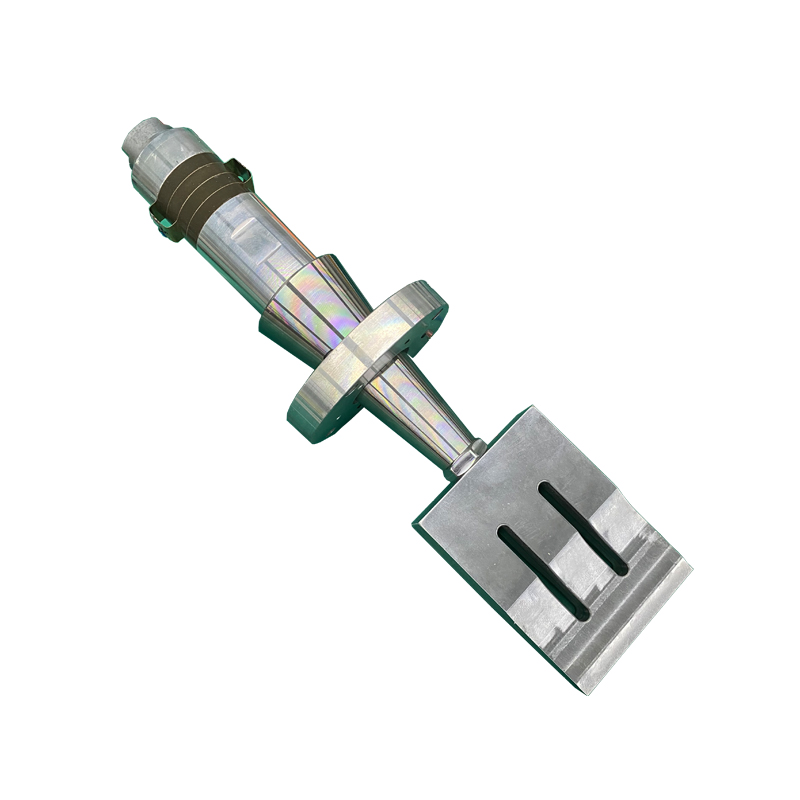

The principle of ultrasonic welding transducer is similar to that of cleaning transducer. It also achieves high frequency vibration with large amplitude by applying prestress to counteract the expansion stress of piezoelectric ceramics. Because the welding transducer requires a large instantaneous power, it has high requirements for materials and processes, so it is a high-power acoustic transducer. Usually, the ultrasonic welding of plastic, metal and other materials is completed by combining the horn and the working head to form a high power, large amplitude vibration system.

Ultrasonic welding is to generate high-frequency friction and heat on the contact gap surface of the welded object under pressure through the ultrasonic vibration generated by the transducer, so as to achieve the purpose of thermal fusion welding.

Ultrasonic welding transducer is a kind of high-power transducer working in gaps or pulses, and its power is generally calculated by instantaneous peak power.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

China Ultrasonic Welder Converter Horn Manufacturer and Supplier For Turntable Ultrasonic Welding Machine_Ultrasonic Welder_Pulisonic Ultrasonic

Last:15KHZ/20KHZ Ultrasonic Cavitation Welder Converter Horn For Automatic Turntable Ultrasonic Welding M

Next:暂无