In addition, the increasing awareness of environmental protection has prompted industrial ultrasonic welding machine generators to pay more attention to energy conservation and emission reduction in their design. Adopting high-efficiency power conversion technology to reduce energy loss during the conversion process; Optimize heat dissipation design to ensure stable operation of the power supply even under high-intensity work, reducing additional energy consumption caused by overheating. These measures not only reduce the operating costs of enterprises, but also contribute to promoting green manufacturing.

The power supply of industrial ultrasonic welding machine generator is expected to achieve a more intelligent upgrade. Through remote monitoring and data analysis, enterprises can grasp the real-time operation status and production efficiency of equipment, predict and solve potential problems in advance, and further improve the flexibility and response speed of production lines. At the same time, customized design based on user needs will also become a development trend, meeting the special needs of different industries and application scenarios, and promoting industrial ultrasonic welding technology to a higher level.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

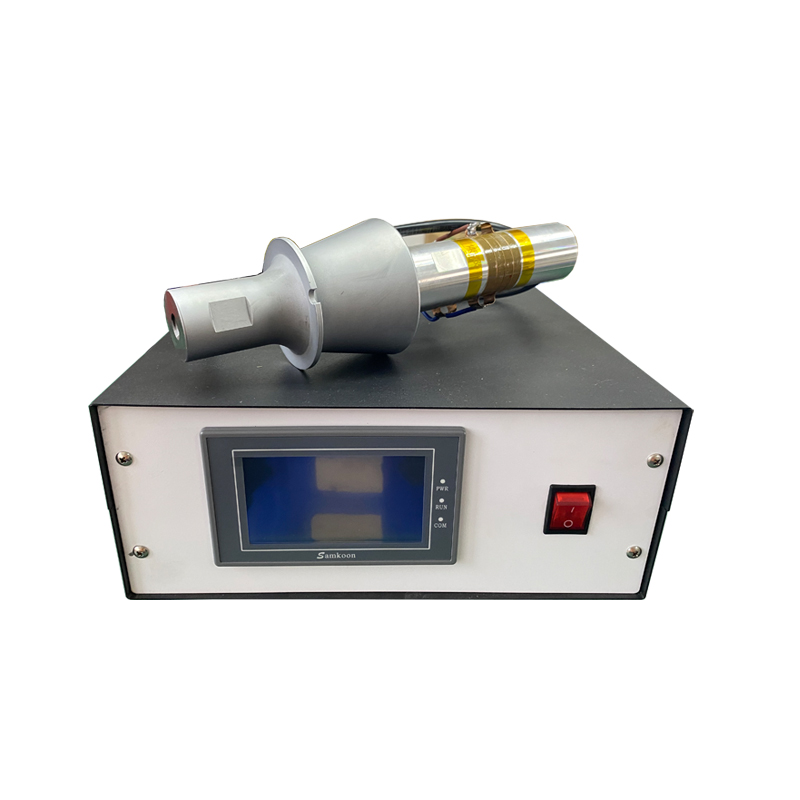

1800W Industrial Ultrasonic Welding Power Generator Transducer Booster Horn For Aluminum Ultrasonic Metal Welding Equipment_Industry news_Pulisonic Ultrasonic

Last:Ultrasonic Sound Generator Power Supply Ultrasonic Generator Ultrasonic Cleaning Generator For Ultra

Next:2600W Industrial Ultrasonic Welding Frequency Generator Transducer Booster Horn For Metal Wire Ultra