With the strengthening trend of intelligence and automation, industrial ultrasonic welding systems are gradually integrating into intelligent manufacturing systems. By integrating advanced sensors, control systems, and data analysis software, real-time monitoring and precise control of the welding process are achieved. This not only significantly improves production efficiency and product quality, but also provides valuable production data support for enterprises, helping them optimize production processes and achieve refined management.

The industrial ultrasonic welding system is expected to showcase its unique charm in more emerging fields, such as wearable devices, new energy batteries, etc., injecting new vitality into the rapid development of these industries. Meanwhile, with the increasing awareness of environmental protection, ultrasonic welding, with its pollution-free and low-energy characteristics, will play a more important role in promoting green manufacturing and achieving sustainable development goals.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

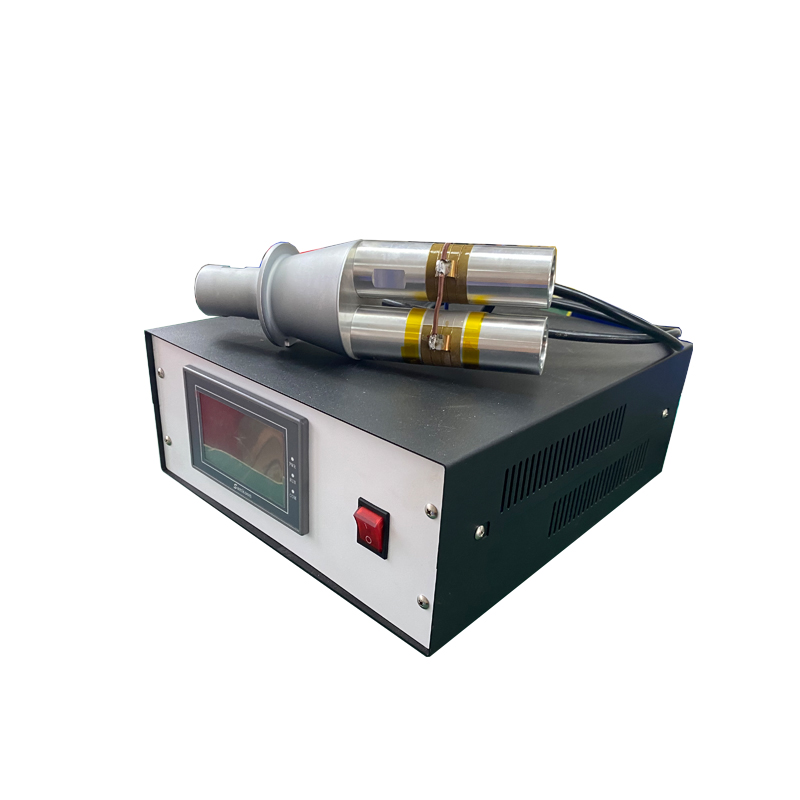

2600W Industrial Ultrasonic Welding Frequency Generator Transducer Booster Horn For Metal Wire Ultrasonic Welding Machine_Industry news_Pulisonic Ultrasonic

Last:1800W Industrial Ultrasonic Welding Power Generator Transducer Booster Horn For Aluminum Ultrasonic

Next:Industrial Ultrasonic Welding Driver Generator Transducer Booster Horn For Ultrasonic Sealing Lanyar