Ultrasonic welding technology has become an important driving force for green manufacturing due to its pollution-free and low-energy consumption characteristics. With the deepening global emphasis on the concept of sustainable development, more and more companies are adopting ultrasonic plastic welding systems to replace traditional welding or bonding processes, in order to reduce the emission of harmful substances and protect the ecological environment.

The ultrasonic plastic welding system will continue to develop towards integration, modularization, and customization. By seamlessly integrating with other automation equipment, a more complete production line solution is formed, further enhancing the level of production automation and flexibility. In addition, customized ultrasonic welding solutions will continue to emerge to meet the diverse and personalized needs of specific industries or products. In short, the ultrasonic plastic welding system, as a powerful assistant in modern manufacturing, will play a more important role in promoting industrial upgrading and green development.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

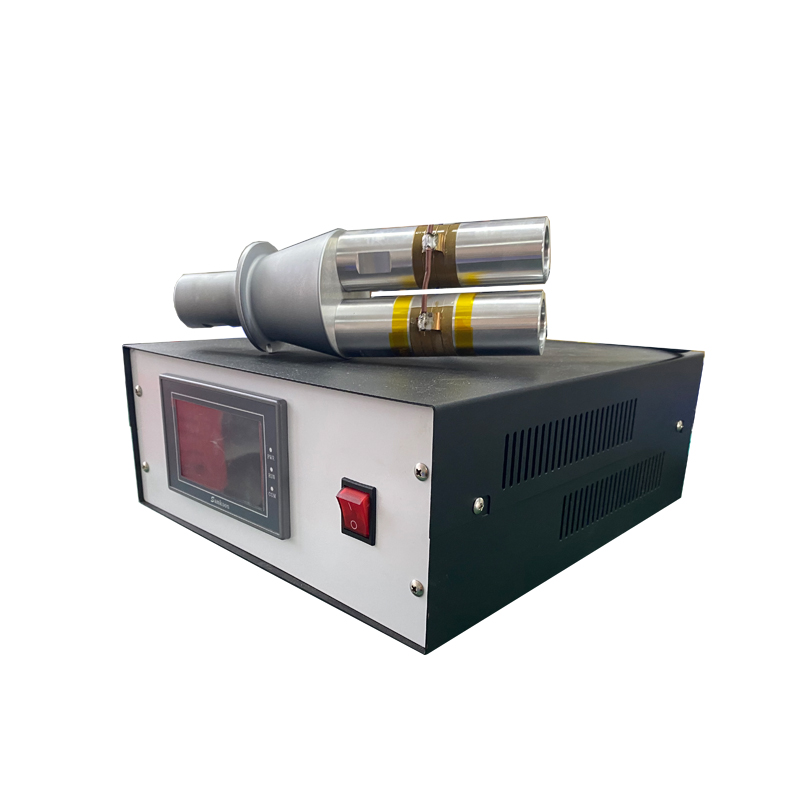

Industrial Ultrasonic Welding Driver Generator Transducer Booster Horn For Ultrasonic Sealing Lanyard Welding Ribbon Machine_Industry news_Pulisonic Ultrasonic

Last:2600W Industrial Ultrasonic Welding Frequency Generator Transducer Booster Horn For Metal Wire Ultra

Next:2000W Ultrasound Welding Frequency Control Generator Transducer Booster Horn For Ultrasonic Plastic