The increasing awareness of environmental protection has also prompted the ultrasonic plastic welding machine system to pay more attention to sustainability in material selection. More and more manufacturers are adopting recyclable or biodegradable plastic materials, and ultrasonic welding technology, with its low energy consumption and pollution-free characteristics, perfectly meets the needs of green production. This not only helps reduce the impact on the environment, but also aligns with the global pursuit of circular economy and sustainable development.

The ultrasonic plastic welding machine system, as an important tool in modern industrial manufacturing, has broad and bright development prospects. With the continuous innovation and expansion of technology applications, we have reason to believe that this field will usher in a more brilliant tomorrow, contributing important forces to the transformation, upgrading, and sustainable development of the global manufacturing industry.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

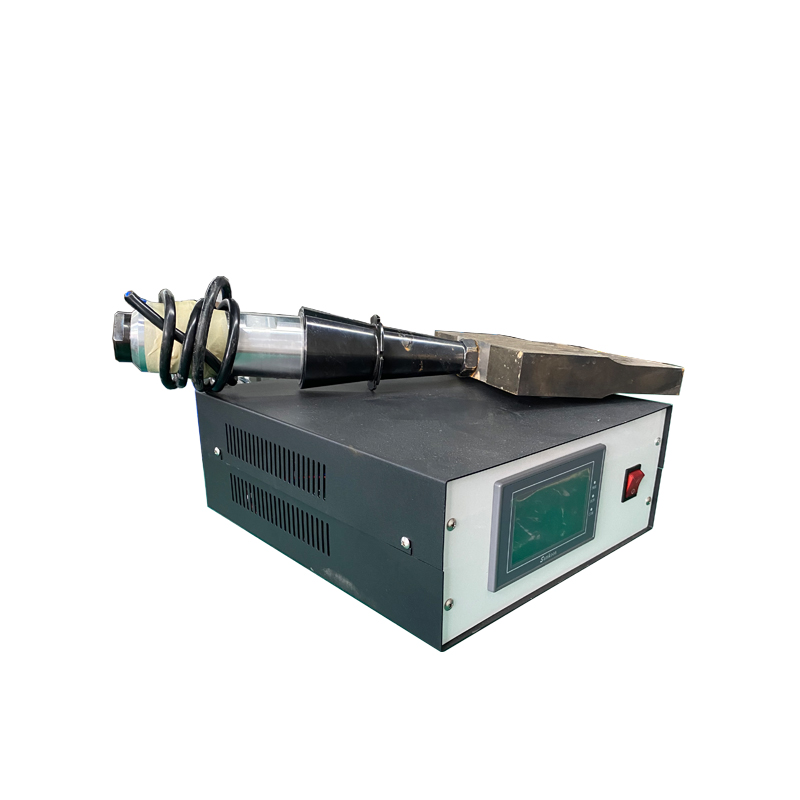

2000W Ultrasound Welding Frequency Control Generator Transducer Booster Horn For Ultrasonic Plastic Bag Welding Machine_Industry news_Pulisonic Ultrasonic

Last:Industrial Ultrasonic Welding Driver Generator Transducer Booster Horn For Ultrasonic Sealing Lanyar

Next:2600W Various Frequency Ultrasonic Welding Generator Transducer Booster Horn For Ultrasonic Non Wove