The application of high-power ultrasonic welding technology is more subtle and precise. It can complete the assembly and packaging of precision medical devices, such as syringes, catheters, and other disposable medical supplies, without damaging the activity of biological products. This non-contact welding method avoids the pollution risk that traditional welding may bring and sets a new benchmark for the aseptic production of medical products.

The high-power ultrasonic welding system is gradually achieving intelligent upgrading. By integrating advanced sensor technology, machine vision, and artificial intelligence algorithms, the system can automatically detect welding quality, adjust welding parameters in real time, and even predict and avoid potential failures, greatly improving production efficiency and product quality. In the future, with the continuous advancement of technology and further reduction of costs, high-power ultrasonic welding systems will undoubtedly demonstrate their unique charm in more fields, promoting the development of industrial manufacturing towards a more efficient, green, and intelligent direction.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

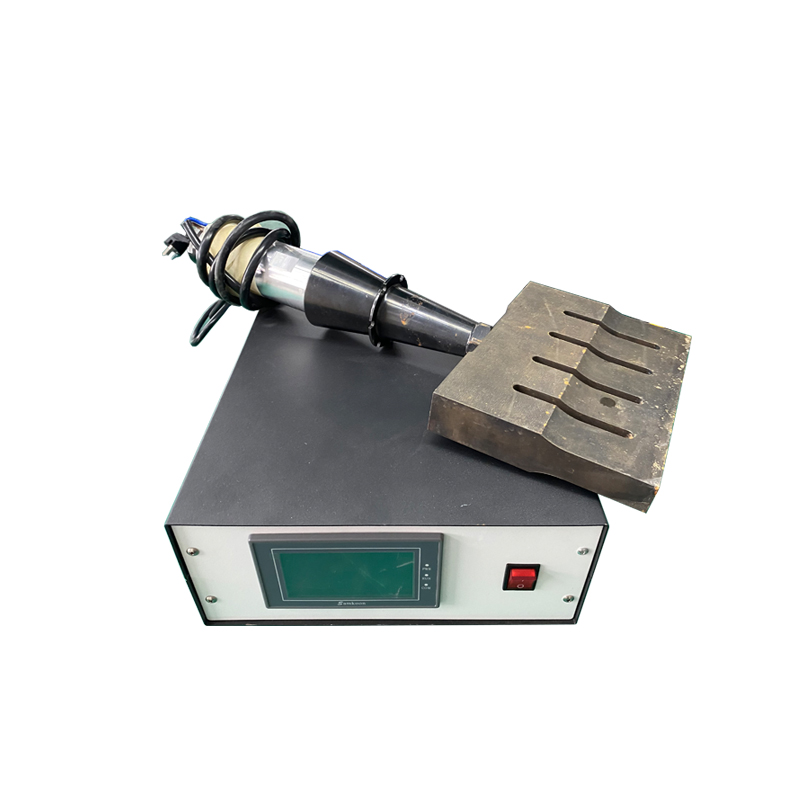

2600W Various Frequency Ultrasonic Welding Generator Transducer Booster Horn For Ultrasonic Non Woven Welding Machine_Industry news_Pulisonic Ultrasonic

Last:2000W Ultrasound Welding Frequency Control Generator Transducer Booster Horn For Ultrasonic Plastic

Next:3200W Various Frequency Ultrasonic Welder Generator Transducer Booster Horn For Ultrasonic Solar Pan